Tech-enabled traceability: transforming fishing with AI

Spotted: As the world’s oceans continue to experience the damage caused by illegal, unreported, and unregulated (IUU) fishing practices, marine proteins continue to become more expensive. To help combat the effects of overfishing and other harms that come from IUU, the UN’s Food and Agricultural Organization (FAO) is encouraging countries to commit to Catch Documentation Schemes (CDS). While compliance and participation are voluntary, so much of the world’s ability to reverse climate change relies on healthy oceans – and that, in turn, relies on more organisations and nations developing fully traceable fish supply chains.

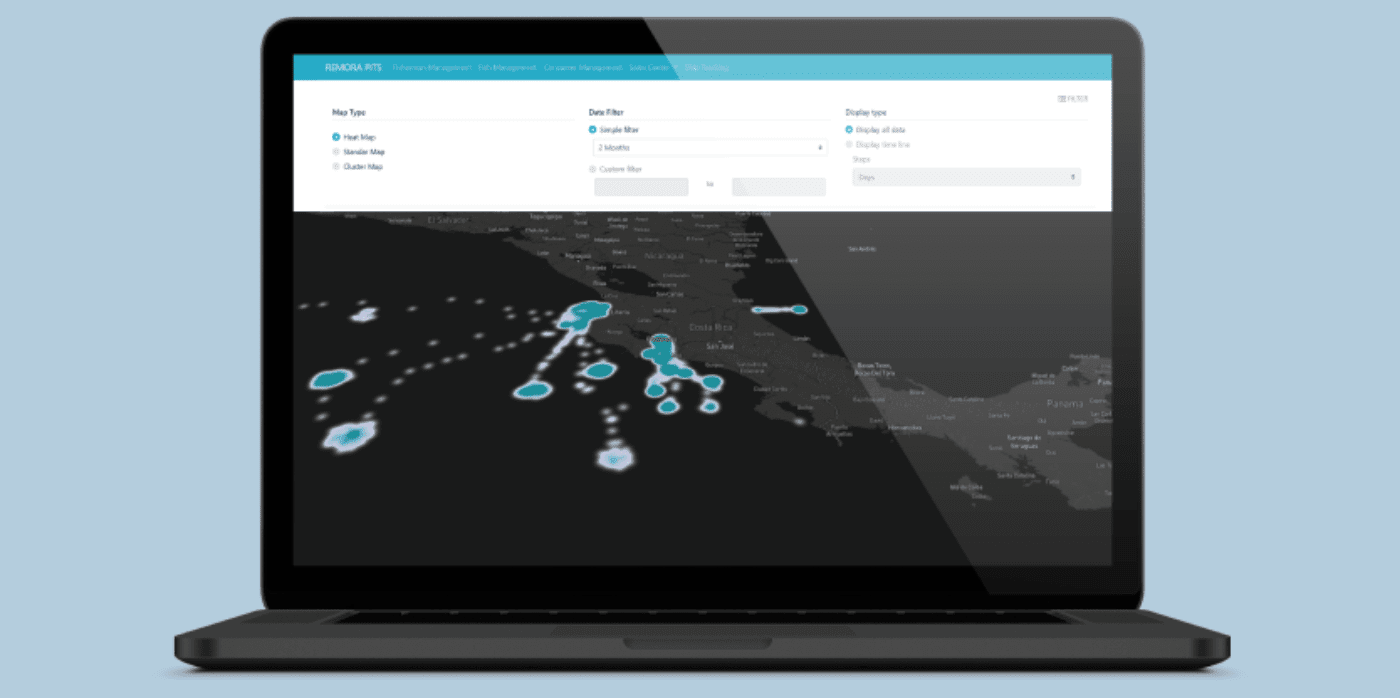

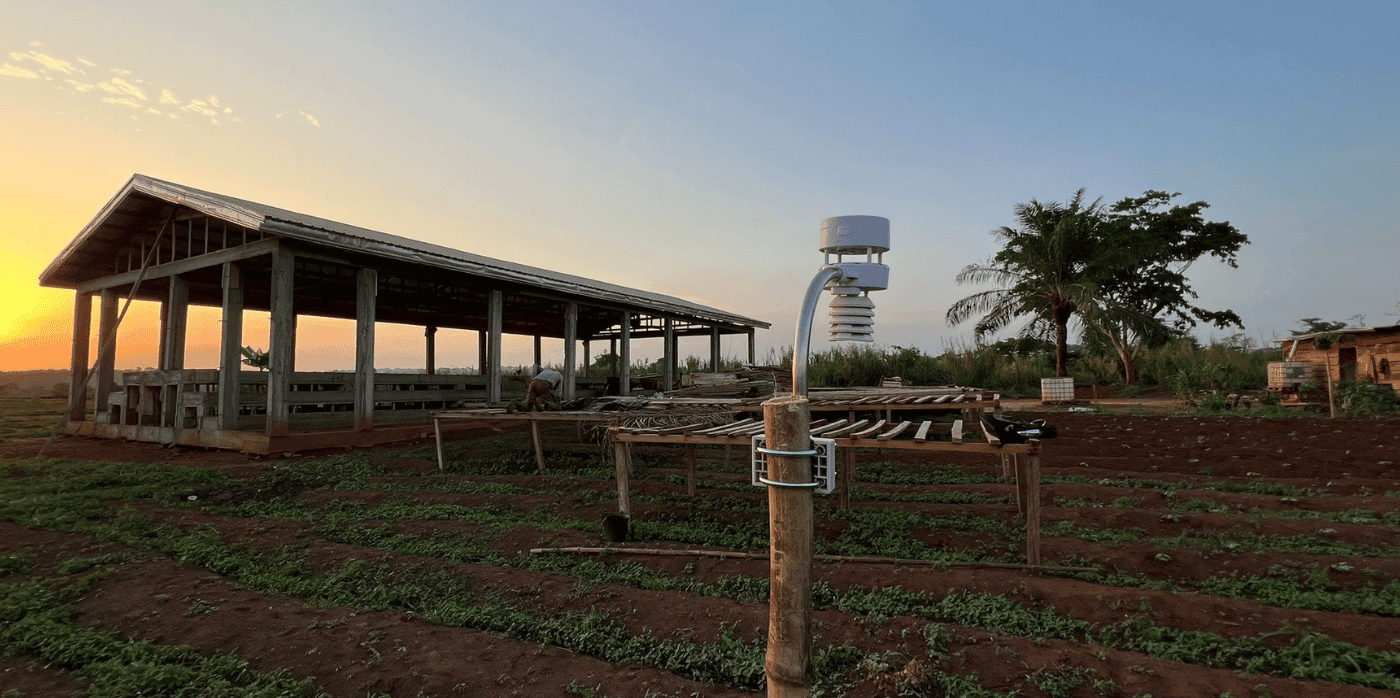

Costa Rican marine technology company Remora is filling the knowledge gap with a set of digital tools designed to increase transparency at every stage of the fishing process, from sea to plate. The company’s Internet of Things (IoT) Vessel Monitoring System makes tracking small boats affordable and provides a wealth of data in addition to that gathered by the tracking of large fishing boats. At landing and unloading locations, Remora’s Smart Scale uses image processing and artificial intelligence (AI) to measure the weight and dimensions of every fish and save that information to the cloud. Each fish is assigned a digital tag that is then used throughout its journey to the end consumer.

Also being developed by the company is a mobile app called WhatsFish to connect fishers with marketplaces and provide consumers with information on their food. All three tools contribute to Remora’s aggregator Fishing Data Platform that compiles information for big-picture analysis of the fishing industry, environmental conditions, consumer behaviour, and more. Remora is running a pilot programme in Cabuya, Costa Rica, with 15 fishing boats.

Seafood is such an important part of the global diet that innovations seeking ways to improve the health of the world’s oceans are focusing on both wild fishing practices and farmed production. Innovations in Springwise’s library include solar-powered tanks for land-based tuna farming and precision technology to reduce bycatch.

Written By: Keely Khoury