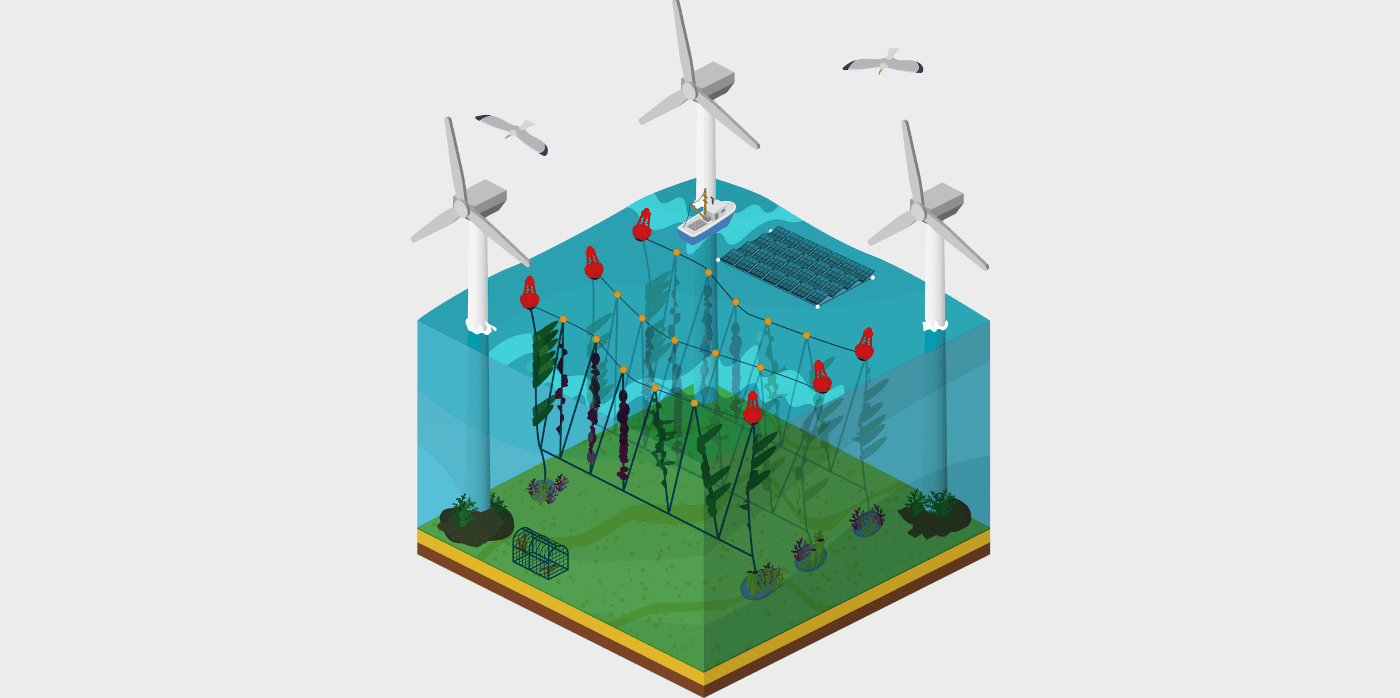

Growing seaweed between offshore wind turbines

Spotted: The global commercial seaweed market was valued at almost $17.9 billion (around €16.9 billion) in 2021 and projected to keep growing. This growth is driven by increased use of seaweed in food and cosmetics, and its use as a fertiliser. However, seaweed is disappearing from many places where it used to thrive because of global warming.

At the same time seaweed farming is becoming more difficult, the number of offshore wind farms is growing. Now, non-profit North Sea Farmers hopes to put the two together by locating seaweed farms between offshore wind turbines. North Sea Farmers plans to install its first seaweed farm, located off the coast of the Netherlands, this year and begin harvesting in Spring 2024. The 10-hectare farm is expected to produce at least 6,000 kilogrammes of fresh seaweed in its first year.

The demonstration project will be the world’s first commercial-scale seaweed farm located between offshore wind turbines. The aim is to kickstart more innovation in seaweed agriculture.

Eef Brouwers, Manager of Farming and Technology at North Sea Farmers, said: “Potentially, up to 85,000 full-time jobs could be created in the European seaweed sector by replicating North Sea Farm 1 across the North Sea.”

The project has received €1.5 million in funding from Amazon’s Right Now Climate Fund, which will be spent on constructing the farm.

Seaweed is not only used in food and cosmetics. Springwise has also spotted a seaweed extract that could reduce the methane emitted by cattle, a seaweed-based packaging, and the use of seaweed-derived materials to prevent dendrite growth in batteries.

Written By: Lisa Magloff