Turning sawdust into high-value green biochemicals

Spotted: Petroleum-based chemicals are an essential part of various industries, from cosmetics to medicine. However, the reliance on fossil fuels also contributes large amounts of CO2 to the atmosphere – almost 4.6 million metric tonnes from the UK petrochemical industry alone. To change this, startup Sonichem has developed biorefinery technology that can convert low-value woody biomass, such as sawdust, into high-value renewable biochemicals.

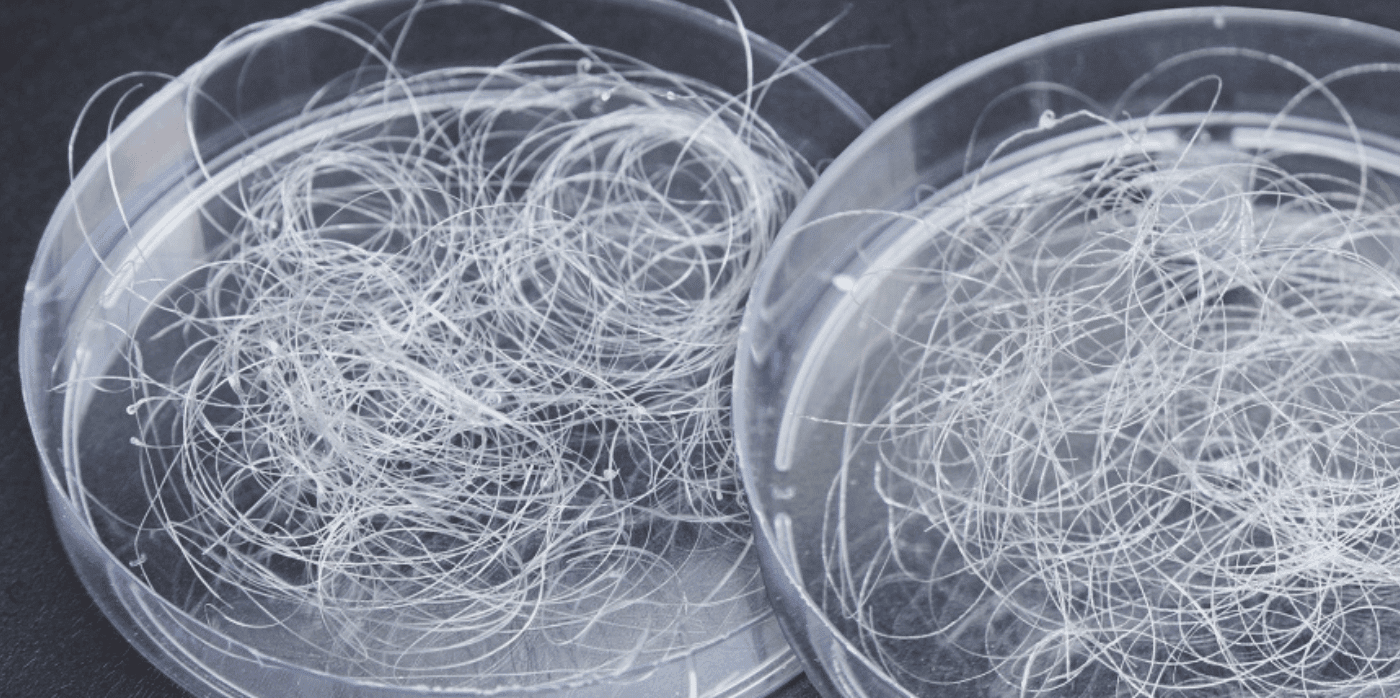

Sonichem uses ultrasound technology to break the chemical bonds in biomass feedstock to free up the cellulose, sugars, and lignin. These fractions are processed through recovery units and can then be used to produce high-quality biochemical products. The company claims that for every £1 of sawdust, its technology can create £8 worth of sustainable chemicals.

The use of ultrasonic energy allows Sonichem to fractionate the biomass at lower temperatures and pressures than comparable processes, meaning less energy is used. The company is also able to recover the organic solvents it uses for the process, reducing the amount of virgin chemicals needed each time.

Sonichem recently raised £1.2 million (around €1.4 million) in a pre-series A round of funding. The investment will be used to accelerate the development of the technology, continue research, undertake intellectual property generation, and finalise the design and location of the company’s commercial biorefinery plant, which will be located in the north of the UK.

Springwise has spotted other innovations that use biomass to sustainably create chemicals and materials, including a company using rice husks to produce silica for tyres and a process that converts air pollution into plant fertiliser.

Written By: Lisa Magloff