Judging for the 11th A+Awards is now underway! While awaiting the Winners, prepare for the upcoming Architizer Vision Awards, honoring the best architectural photography, film, visualizations, drawings, models and the talented creators behind them. Learn more and register >

Light-emitting diode (LED) video displays take architectural design to a new level of brilliance, transforming the city streets and skylines into spectacular sights. Technology meets design and art to cover entire building façades for a high-impact passerby engagement.

Unfortunately, as mesmerizing as this visual spectacle can be, these luminous building skins add to the high amounts of human light pollution. This effect increases the brightness of the sky at an alarming pace.

Building Skins

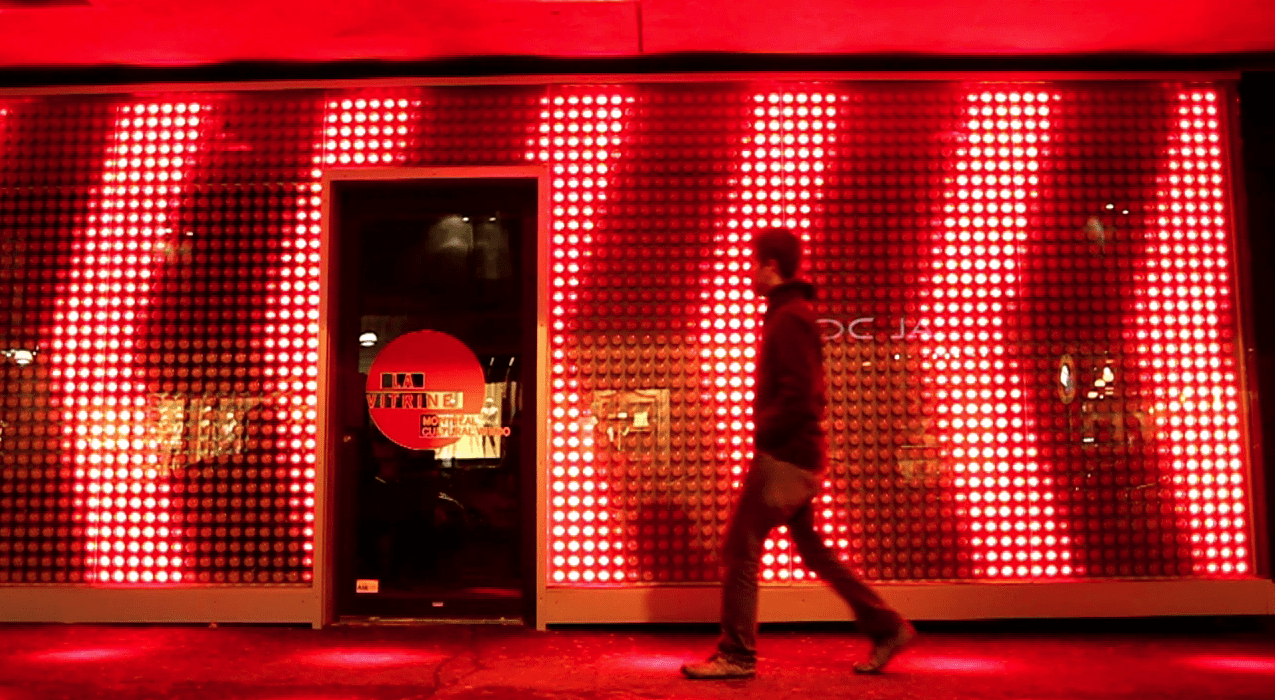

Digital façades redefine how we think of architecture and, more specifically, building skins. Entire walls become giant canvases with lighting as an artistic form of visual communication. LED technology has reached the point where screens of digitally controlled nodes emitting vivid colors can form an integral part of the architectural expression, adapting to various planes and configurations. The outcome achieves extraordinary visual effects, blending light, media and art. Never have buildings been brighter and more scintillating.

Interactive LED Media façade for La Vitrine Culturelle in Montreal’s Cultural district. Photo by Moment Factory via Architizer

Dynamic and Expressive

With free-flowing and vivid colors, buildings become more dynamic and expressive. At dusk, architecture becomes secondary, and the light installations that cover entire building surfaces take centerstage. Then, the urban landscape, as experienced during the daytime, gives way to a transformed setting where light and media become the main attraction. Expansive installations fill the streets with a futuristic flair blending the real and virtual worlds. This fantastic atmosphere captures passersby’s and drivers’ attention, heightening their senses and triggering feelings. The ambient sound intensifies the experience, unsettling yet captivating.

Design for the Senses

This sensory architecture affects how passersby interact with their immediate surroundings. It influences feelings such as mood, energy levels and appetite. Based on all of these attributes, digital façades serve as powerful marketing tools to attract customers for retail establishments, enhance the fan experience for sports venues and create brand identities for corporate businesses. Digital façades have become an effective communication vehicle that transforms urban centers into a new media form, like print (newspapers), broadcast (television) or the internet (social media). This luminous communication technology allows passersby to interact with the displayed content, whether it is news, advertising, weather forecasts or social media activity.

Interactive digital screens deliver information in real-time. Photo by Cheung Yin via Unsplash

Pros and Cons

Technological advances continuously make LED lighting more affordable and energy-efficient. Light quality is continuously improved. LEDs have a very long life compared to other types of lighting, such as high-pressure sodium lamps traditionally used in street lighting and require virtually no maintenance or replacement. Yet, concerns are growing about the impact of blue emission excess on the one hand and light pollution causing the “skyglow” phenomenon on the other hand. Digital façades put off an incredible amount of light which, to some degree, contributes to light pollution generated by electric lights’ nighttime glow. This effect appears to be intensifying, especially in dense urban areas, with the artificial brightening of the night sky.

Sky glow over Hong Kong due to lighting pollution. Photo by Patrick on Unsplash

New Lighting Strategies

Also, environmental studies show that LED lights emit relatively high levels of blue light, a wavelength that negatively impacts human health and wildlife. While new light strategies are explored to mitigate the impact on human well-being and ecological systems, LEED (Leadership in Energy and Environmental Design) promotes the minimization of light pollution by reducing light emissions, especially up to the sky. Perhaps a period of complete night darkness would be beneficial but unrealistic, so finding the most efficient and safe lighting system seems to be a priority. LED technology has the potential for improvement, and city authorities can regulate the amount of light emission per building, a compromise worth exploring.

Digital façades undoubtedly add to the character of buildings while becoming part of the urban landscape, creating exciting environments, attracting visitors and spurring business. Cities like New York, Hong Kong and Dubai exemplify the striking development of buildings incorporating digital façades. These eye-catching buildings shape the skylines of these cities, captivating the mind, rewarding the eye, enhancing the atmosphere and evoking powerful emotions.

Judging for the 11th A+Awards is now underway! While awaiting the Winners, prepare for the upcoming Architizer Vision Awards, honoring the best architectural photography, film, visualizations, drawings, models and the talented creators behind them. Learn more and register >