Verifiable plastic recycling technology – Springwise

Spotted: According to the Organisation for Economic Co-operation and Development (OECD), just 9 per cent of global plastic waste is recycled. This problem is particularly acute in Africa, where poor rubbish collection and a lack of recycling facilities has not stopped wealthier countries from dumping their excess trash. This is the problem Nigerian cleantech company Kaltani aims to solve with its collection centres and recycling factory.

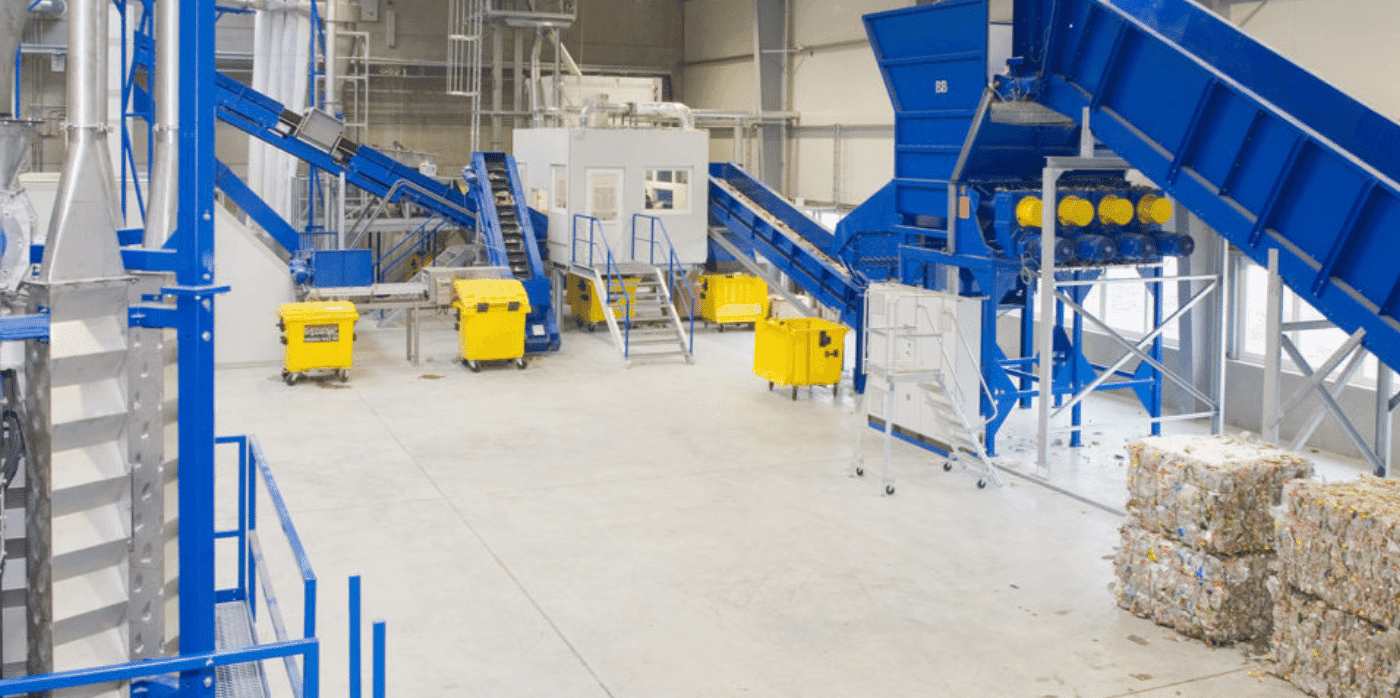

Kaltani operates its own collection and aggregation centres, where plastic waste is delivered by waste pickers before being brought to dedicated recycling factories. There it is aggregated and processed. Plastics are converted into hot washed PET flakes, then PE and PP pellets which are sold to Fast-moving consumer goods (FMCG) companies for thermoform, sheet, packaging, bottling, and fibre applications.

The company was founded by petroleum engineer Obi Charles Nnanna, who was motivated

by the high pollution levels in Africa, and the numbers of people earning a precarious living by picking through waste. Kaltani uses data analytics, predictive analytics, and geo-mapping to ensure transparency and traceability throughout the entire value chain. But the company also works to empower waste pickers by providing a more stable and predictable income.

The startup recently raised $4 million (around €4.1 million) in a funding round. The money will be used to open new collection and aggregation centres across Nigeria and increase its staff to over 500 people.

Plastic waste is everywhere – so solutions also need to be everywhere. Springwise has spotted a huge number of innovative solutions to the problem of plastic waste. Recent ideas have included the use of PPE waste to strengthen concrete and the creation of a self-healing, recyclable plastic.

Written By: Lisa Magloff