Architizer is thrilled to announce the winners of the 11th Annual A+Awards! Interested in participating next season? Sign up for key information about the 12th Annual A+Awards, set to launch this fall.

Necessity is the mother of invention, and it has plenty to answer for in design and architecture. This is immediately evident at The Greenhouse, a zero-waste theatre complete with performance space, standalone screening room, bar and box office

Visiting three prime spots in London this summer, the first run, at Royal Docks, was part of Sea Change, a cultural program about climate. Next, the space holds a residency at Canary Wharf, from 19th June until 14th July, before finishing at Battersea Power Station between 7th August and 3rd September. A striking, if understated, approach to experimental venue design, the venue is hand-built from recycled and reused materials. After revealing his background in site-specific productions, Artistic Director Oli Savage tells Architizer how the idea came about.

“Around 2016, a close friend, collaborator and colleague of mine put a script on my desk all about eco-terrorism, Swallows. It was a metaphor for violence towards each other and towards the planet by Henry Robert, a really talented writer. I’m interested in space and how a space can make the show work. And from a practice perspective, I’m interested in working holistically. To me, if you’re putting on a show, it’s important that everything around that show reflects the ideas of what that show is talking about. You’d feel a little hypocritical working on a climate piece and having lots of impact and waste,” says Savage.

The Greenhouse is the UK’s first zero waste theatre (C) The Greenhouse Theatre

“A couple of years later, we’re on the Royal Mile in Edinburgh for the Fringe Festival, our show was A Midsummer Night’s Dream. Standing in the pissing rain, handing out flyers to promote the performance, I said to our head of marketing: ‘Surely this isn’t actually a very effective way of getting people through the door’. She said: ‘No, and it causes a lot of waste.’ I started digging into this, and it’s astounding how much waste is created, most of which isn’t recyclable,” he continues. “This is particularly evident in fringe arts.”

With the script for Swallows still in mind, Savage began brainstorming with collaborators, trying to figure out how the show could run at the Edinburgh Fringe and stay true to its climate message. Soon realizing there was no existing facility that could tick all necessary boxes, a decision was made to create a new space. Returning to the Scottish capital twelve months on, The Greenhouse debuted in 2019 with Swallows finally staged and, as Savage puts it, “has been on and off” since.

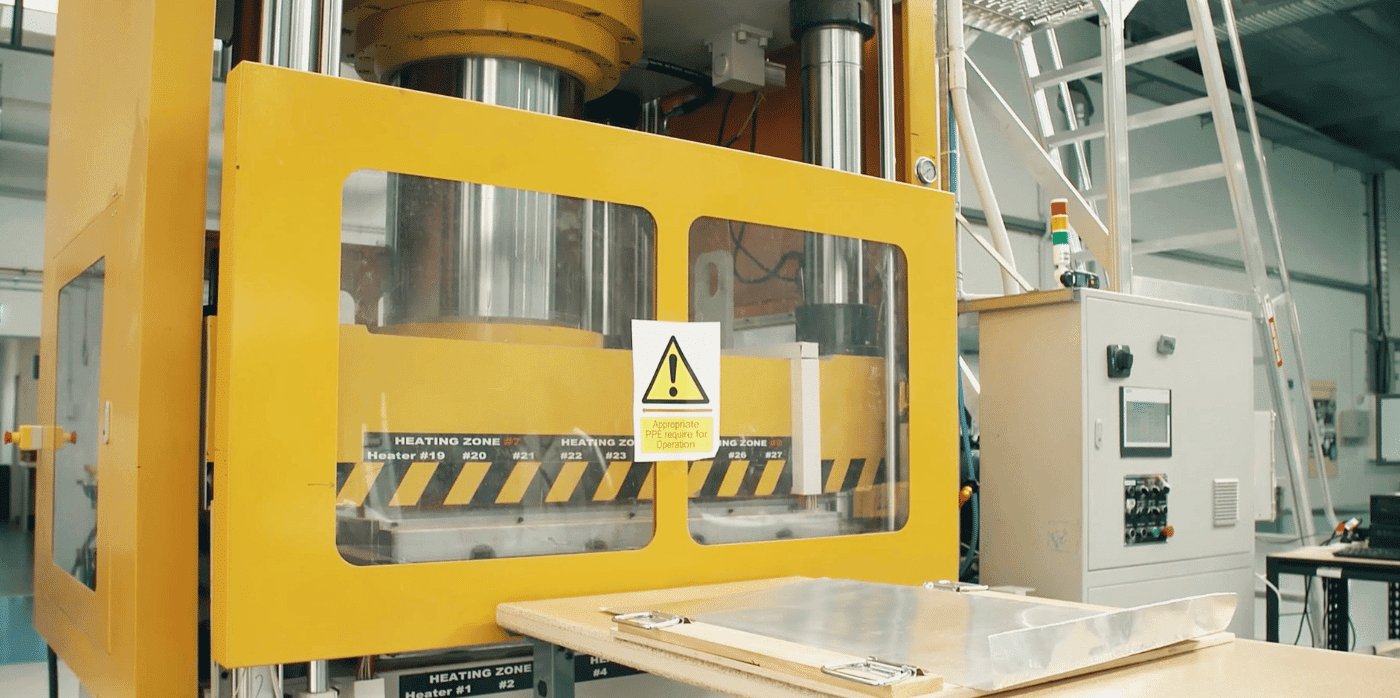

The Greenhouse Theatre under construction in London, 2021 (C) The Greenhouse Theatre

“I just say to people come and see the space,” Savage replies when we ask about the green credentials. “I’d say it’s obvious when you’re inside — this is not making claims that can’t be backed up. In terms of design principles, we were determined to show the materials being using, so the waste is showcased front line for people to see for themselves. And we’re a zero waste theatre, that’s the terminology. There are differences between this and, say, carbon neutral. So all the materials had a life before us, and will hopefully have another life once we’re finished.

“Broadly, the whole thing is built from three materials. Timber framing and wood pallet cladding, around a triangular lighting truss skeleton. The roof is made from corrugated PVC,” he explains. “As you’re designing, you’ve got to be thinking, if we want this to be zero waste, what materials do we have access to? How are we going to be able to deliver this in a zero waste way. Another interesting thing was our first situation for the venue didn’t have the possibility of any power. So we came to this conclusion it needed to be naturally lit with a clear plastic roof. That’s now one of my favorite aspects of the venue.”

The Greenhouse Theatre at Canary Wharf, London (C) The Greenhouse Theatre

For Savage, The Greenhouse Theatre design is all about dialogue between different demands. The requirements stipulated by the project itself — zero waste, low impact — and the need to develop a space suitable for creative practice. Form meeting function deep in the grass roots.

“It was also a necessity for me that it was in the round. That was a big thing. If I’m working in a theatrical space, it has to be either in the round or traverse. It creates this sense of community,” says Savage, pointing out all this is replicable. “Reclaimed timber is easy to come by. There are lots of facilities around the UK, recycling centres that take surplus timber from sites, clean it, then sell it on. Most are charities, awesome organizations. The trussing was from a lady who used it for trade shows, retired and sold it to us for a really good price. The plastic, I think it was a builder who bought it for a project that was cancelled or over-ordered.”

“The headline is that it’s not that hard. It seems like it’s challenging, but so much theatre, at university for example, relies on borrowing and reuse,” he adds. “We have a consultancy, working with filmmakers, other theatre makers, creatives, to help them towards zero waste. There’s a lack of provision for fringe artists in terms of this type of thing. It’s tricky, though. One of the hardest things is a lot of people expect work for free… Obviously, my goal as a person is to have the most impact and help. But the reality is some try to take advantage… If we can’t monetize, I’m not going to have a business, and we’re not gonna be able to run.”

Architizer is thrilled to announce the winners of the 11th Annual A+Awards! Interested in participating next season? Sign up for key information about the 12th Annual A+Awards, set to launch this fall.

Waste is at the forefront of many global sustainable initiatives. Why? Because we all contribute to waste. It is part of our daily lives and, realistically, isn’t going anywhere. Currently, we are running out of space to house our waste. In the US alone, a whopping 292 million tons of trash was generated in a single year. To make room for all this waste, natural habitats have been destroyed, greenhouse gas emissions have risen, and taxes have gone up to offset the costs of running expensive landfills.

Waste is at the forefront of many global sustainable initiatives. Why? Because we all contribute to waste. It is part of our daily lives and, realistically, isn’t going anywhere. Currently, we are running out of space to house our waste. In the US alone, a whopping 292 million tons of trash was generated in a single year. To make room for all this waste, natural habitats have been destroyed, greenhouse gas emissions have risen, and taxes have gone up to offset the costs of running expensive landfills. For some real-world context, Jessica shared a bit on Inpro’s

For some real-world context, Jessica shared a bit on Inpro’s